يقوم العديد من الشركات المصنعة بتصنيع جميع المفاصل الدائمة لجسم الشاشة باستخدام براغي التثبيت.

الهيكل الداعم / الأساس.

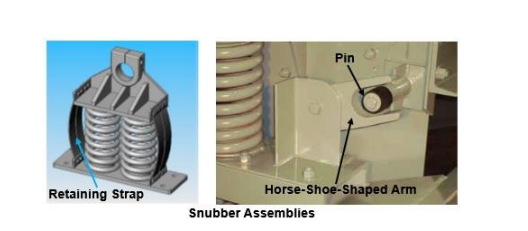

يوضح الشكل أعلاه البناء النموذجي لنوعين من مجموعات snubber. في حالة

التجميع باستخدام أشرطة الاحتفاظ، فإن أشرطة التثبيت تحد من الحركات الكبيرة للوحدة بينما

في حالة التجميع باستخدام ذراع على شكل حدوة حصان محمل بنابض، فإنها تتلامس

مع امتداد الدبوس لتقييد حركة الوحدة. ومع ذلك، من أجل التشغيل السليم للمقبض

، يجب إحكام ذراع مجموعة المقبض على شكل حدوة حصان والمحملة بنابض

وفقًا لتوصية الشركة المصنعة.

ألواح المنحدرات القابلة للتعديل

في كثير من الأحيان، يتم تزويد الحواجز المائلة ذات أسطح الدعم المقسمة التي تمكن المقاطع من الترتيب

على شكل قوس (شبكات الموز) بألواح انحدار قابلة للتعديل عند

نهايات التغذية والتفريغ. لتحسين الكفاءة، يمكن تعديل هذه الألواح وفقًا

لمتطلبات العملية. سيؤدي رفع قسم نهاية التغذية إلى زيادة سرعة التغذية وتقليل

عمق السرير. في حين أن رفع طرف التفريغ سوف يقلل من السرعة

ويزيد من عمق السرير.

قاعدة محرك محورية وشد الحزام

في حالة تشغيل الحزام على شكل V، يمكن تزويد محرك التشغيل بقاعدة محرك محورية لتوفير

شد موحد للحزام في جميع الأوقات (للاعتناء بالتمدد والتمدد الطبيعي للحزام بسبب

ارتدادات البدء/الإيقاف).

لمزيد من المعلومات حول قاعدة المحرك المحورية، يرجى الاطلاع على المقالة "إنشاء وتشغيل

قواعد المحرك المحورية لمحركات الحزام" على www.practicalmaintenance.net.

احرص. يمكن للأحزمة المشدودة بشدة أن تسبب أضرارًا أكثر خطورة. إذا

كانت الأحزمة مشدودة أكثر من اللازم، فسيتم سحب الإطار المهتز من المربع مع إطار الدعم.

يؤدي التشغيل في هذا الوضع الملتوي إلى ظهور ضغوط يمكن أن تؤدي إلى فشل الزنبرك

وتعب المعدن والتشقق واللحامات المكسورة في الإطار الاهتزازي.

بالإضافة إلى ذلك، فإن الالتواء سوف يؤثر على سعة الشوط، وبالتالي يؤثر على تدفق المواد

وكفاءة الغربلة.

تضع الأحزمة المشدودة عبئًا إضافيًا على محامل الآلية وهو أمر غير ضروري وقد

يؤدي إلى تلف المحركات وقواعدها. من الناحية المثالية، يجب أن تكون الأحزمة مشدودة بدرجة كافية حتى

لا تنزلق أثناء بدء التشغيل. تتوفر الشاشات الاهتزازية

الخاصة بحاوية الغبار في نماذج مغلقة جزئيًا أو كليًا إذا كان الغبار أو الضوضاء يمثل مشكلة، أو عندما تتطلب اللوائح مثل هذا التحكم. هواء الربيع

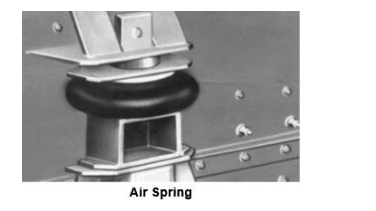

توفر النوابض الهوائية أقصى قدر من عزل الاهتزازات للهياكل التي تدعم

الشاشات الاهتزازية. عملها يشبه عمل المنفاخ، حيث يتوسع أو يتقلص بصمت مع تغيرات

الحمل. هذه النوابض الهوائية مصنوعة من نفس سلك النايلون المتين والمطاط عالي القوة

المستخدم في إطارات السيارات بدون أنابيب. يمكن استخدام أي مصدر هواء مناسب للتضخم.

الإطارات الفرعية (إطارات العزل)

تُستخدم الإطارات الفرعية (إطار إضافي مضاد للاهتزاز) لتقليل قوة الاهتزاز

المنقولة إلى هيكل الدعم. يوصى بها بشدة للشاشات الكبيرة. يوضح الشكل أعلاه

شاشة اهتزازية مع الإطار الفرعي.

العلامات :

اتصل بنا :

بريد إلكتروني : sales@vrvibratory.com شبكة IPv6 مدعومة

شبكة IPv6 مدعومة